PCB Design and Layout Services

Our services

PCB Design and Layout Services

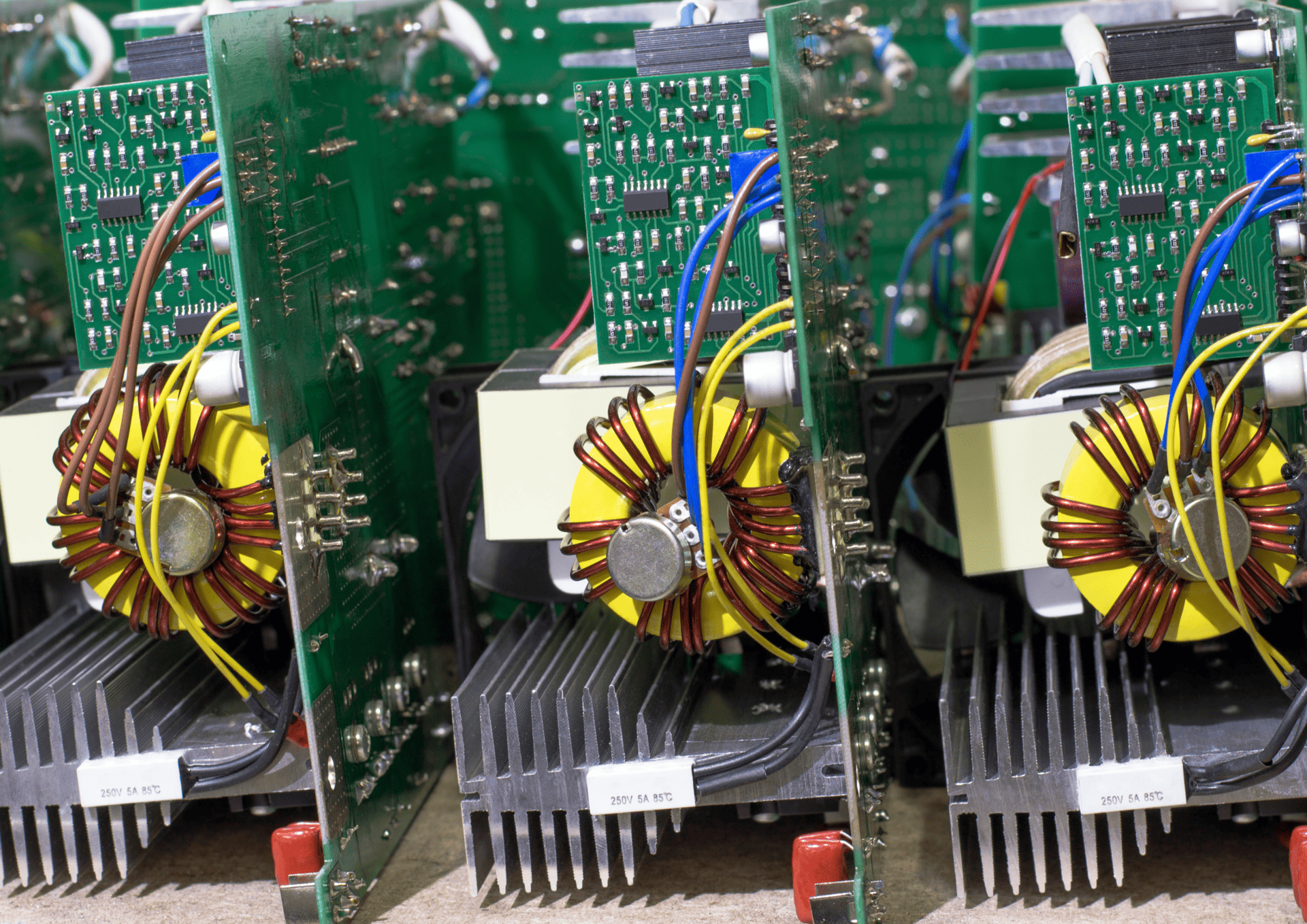

We design printed circuit boards of any complexity: rigid, flexible, multilayer, HDI boards, high-speed PCBs, and other types. Bestzlink’s PCB designer team can create boards from scratch or improve an existing electric circuit design. We will create a prototype, develop embedded software, test the product, and prepare PCB design and layout documentation.

What we do

Bestzlink creates analog, digital, and mixed-signal boards for custom electronics. As a PCB design company, we can provide consultation, evaluate your project, and offer a full cycle of development – from schematics and layout to testing and validation. We use the DFMA approach in our work and can help you with certification and production launch.

What’s included

Technical Specification

Preparing a project specification is an important part of custom PCB design and layout services. It provides a clear vision of the future product and its cost. The document includes technical requirements, block diagrams, deliverables, assumptions, a preliminary bill of materials (BOM), and BOM costs, as well as tools and technologies to be used.

Schematic Design

PCB board design always starts with building a high-level block chart of the device. Then we design schematics. A circuit diagram conveys the connection between integrated circuits (ICs) and discrete components. Our team uses professional CAD software, such as Altium Designer, to define modules and design the connectivity between different elements of the board.

PCB Layout Services

We draw a PCB layout – the physical interpretation of the schematics. We take into consideration the required number of layers and the size of the enclosure, analyze signal integrity, and evaluate electrical limitations to ensure the safety of the product. Proper conductor routing is key to lowering the manufacturing cost. We run DFM/DFA analysis to minimize PCB design revisions, cut development costs, and reduce time to market.

Prototype Fabrication and Testing

Once the layout is ready, Bestzlink’s PCB designers create a Gerber file used to manufacture a prototype and a 3D model of the PCB to make sure it fits the enclosure. We also provide the manufacturer with the data and software necessary to perform an electrical and impedance test. After the prototype is manufactured, we test it in-house to make sure it works as intended.

Assistance with Mass Production

After validating the prototype, we prepare documentation for mass production, help the customer find a manufacturer, and place the order. We can also develop special software, hardware, and testing procedures so that the manufacturer can test each PCB at the factory.

Warranty Period

When the project is finished, we create a full document package that comprises BOM and Gerber files, 3D models, and technical manuals. In addition, we set a warranty period for our PCB design services. During this period, we fix bugs and provide other technical support covered by the warranty. After the warranty period ends, we stay in touch with our customers and provide consultations when needed.

Ready to get your project started?

Contact us today to learn how Bestzlink can empower your organization with innovative technology solutions.